5 minutes to learn it all...

Western analysts have estimated the Market Product Information Management (PIM) of systems at $7 billion in 2019 and predict its growth to 11 billion by 2024.

For more than 10 years I have been engaged in PIM, participating in the development, implementing them on the ground.

I would like to share with you what is PIM and why you do need it, now, more than ever.

Product Information Management can be translated as a system for managing product information. What is it and how important is it for business? Recently I was looking for a designer for a child, and noticed how different information about the same product can be.

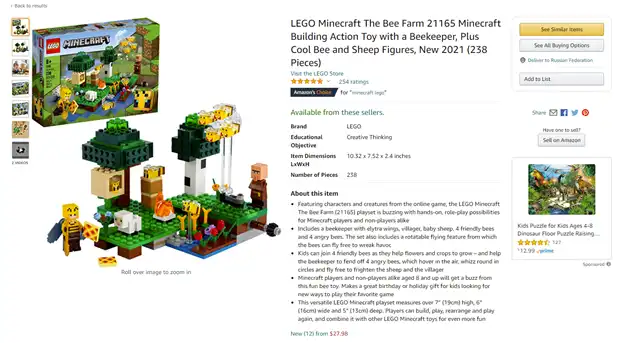

Here is a description of the same product, but on different sites.

First web site :

Second web site :

What is the information about the product ?

Information about the product is not only description, picture and price. It can be very diverse, for example, the TV needs its attributes (you do not buy a TV online if you do not know what its diagonal), for the bike – others, for pizza – its own, etc.

Here’s an approximate list of what might be needed to describe a product:

- Basic data such as product ID, description, etc.

- Hierarchy, that is, to what category belongs to the product (and categories may be different depending on the sales channel, for example on its website it is one, on the marketplace – another, etc.

- Technical specification, attributes such as the TV diagonal, color and size for shoes, etc.

- Product-related files such as images, documentation, videos, etc.

- Marketing data. It can be any tags, attributes for SEO, customer reviews, etc.

- Information required for sale, such as prices, delivery time, etc.

- Specific information for sales channels, for example, categories on marketplaces, specific attributes for each marketplace, etc.

- Localization if sales are in different languages.

- Production information such as certification, allergen availability, composition, etc.

- Logistics information: weight, packaging sizes and without, shelf life, etc.

Now, imagine that you have thousands of items of such goods, and some and millions. That’s to manage all this mass of information that PIM systems have been developed.

What are the benefits of implementing the PIM system?

The first thing a company gets after implementation is to reduce the cost of managing all this information. You will be able to spend less time in the management of your goods, and they will be able to go on sale faster.

Plus, the quality of information is improving. You’ll be sure that all the necessary attributes are filled and checked from your products before they get to the website.

You won’t need to have access to multiple systems to manage your product information. That is, you do not need to think that the name of the product should be corrected in the e-commerce system, but the weight of the product is stored in ERP.

Typically, PIM systems support automation capabilities, so you can automate frequently repetitive operations.

And usually such systems have analytical reports, which will be very useful for the marketing department.

How does PIM work ?

The basic idea behind PIM systems is that they are master systems for product data. That is, all the necessary information about the product should be stored in PIM, and change only in it.

Here is an illustration showing the typical process of a PIM :

Download Product information

In the beginning, we need to upload food information to the system. This can happen in different ways, if you produce the product yourself, then you have to create this information, in which case the person contributes manually, or it comes from internal information systems related to production.

Retailers usually receive this information from suppliers and manufacturers, but this information should be, at least, checked, and often retailers in any case enrich this information, for example, make their photos, etc.

PIM is incoherently connected to other information systems. Usually some of the information comes from ERP (e.g. product ID, price)

That is, the PIM system should be able to import data from different sources. After all, often we cannot dictate to suppliers what format to use for data exchange. We still need to smear the data that we get on those attributes that we have in the system. And it is desirable that this import setting was easy and convenient, because the sources of this data are also constantly changing, we can start to get new products from a new supplier, etc.

Saturation of product information

Once the information enters the system, it is checked. For example, whether all the necessary attributes are filled. Checks can be both human and automatic, usually all PIM systems have the ability to set the logic of checks. And if something is not filled, tasks can automatically be generated for different departments to correct these errors. If there is no picture, the task will be formed for one department, and if the logistics information is not filled – then for another.

In addition to inspections, the product is always classified. You need to put the item in the right category in the hierarchy. And the problem is that there can be many of these hierarchies. The tree of the item can be one, on our website we can show a different classification, each marketplace sets its hierarchy, etc. There are still industry hierarchies, such as ETIM, they also need to be downloaded into the system and classified by them.

That is, the PIM system should support many hierarchies, which also need to be imported and verified.

As I’ve written, each product category has its attributes. That is, it also needs to be managed, it is necessary to enter all these attributes, to expose them to the appropriate categories. Plus, the attributes often change, the business is very dynamic and often you need to store additional information. For example, we decided to make discounts, you need to create appropriate attributes in the product or categories to store it.

Different people can work on the product at saturation stage, so the system should support workflows so that employees clearly understand what is required from them and automatic checks (you need to check the information after the person changes it) and the sharing of access (it is better not to give access to the editing of logistics information to the department that deals with photography).

Unloading food information

And finally, when our products contain all the necessary information and it is checked there is an unloading (export) of information about goods.

Exports are also not an easy thing to do, you need to support all possible formats, for example, different marketplaces oblige you to provide information in a form convenient for them, not for you. Unloading can take place in batch mode (when you unload grocery information once a day, for example) or in real time when information is transferred to other systems immediately after changing and checking the item.

Again, different sales channels require different data, for a printed directory you will need one set of attributes, for the site – another, for the marketplace – the third, etc.

Plus, the data you have in the system is stored in the way that is convenient to you and often they need to be transformed to give to another system, for example to transfer units to another system, etc.

And of course, we want all these export settings to be done in a short period of time, and that there was no need to connect programmers and spend their resources and time.

Now, it becomes clear why companies are willing to spend money on such systems and why this market is measured in billions.

And you, how do you manage Product Information? It would be interesting to read in the comments the opinion of people who do it every day.

This article has been written by Slava Pedak, PIM Technical Expert at Arhis, for 10 years.

Slava has more than 20 years of IT experience in solutions architecture, technical development and technical management.

He hase delivered complex and successful PIM Integration projects all around the world.